Penn Machine Adds Vertical Turning Center to its Transit Division’s Production Capabilities

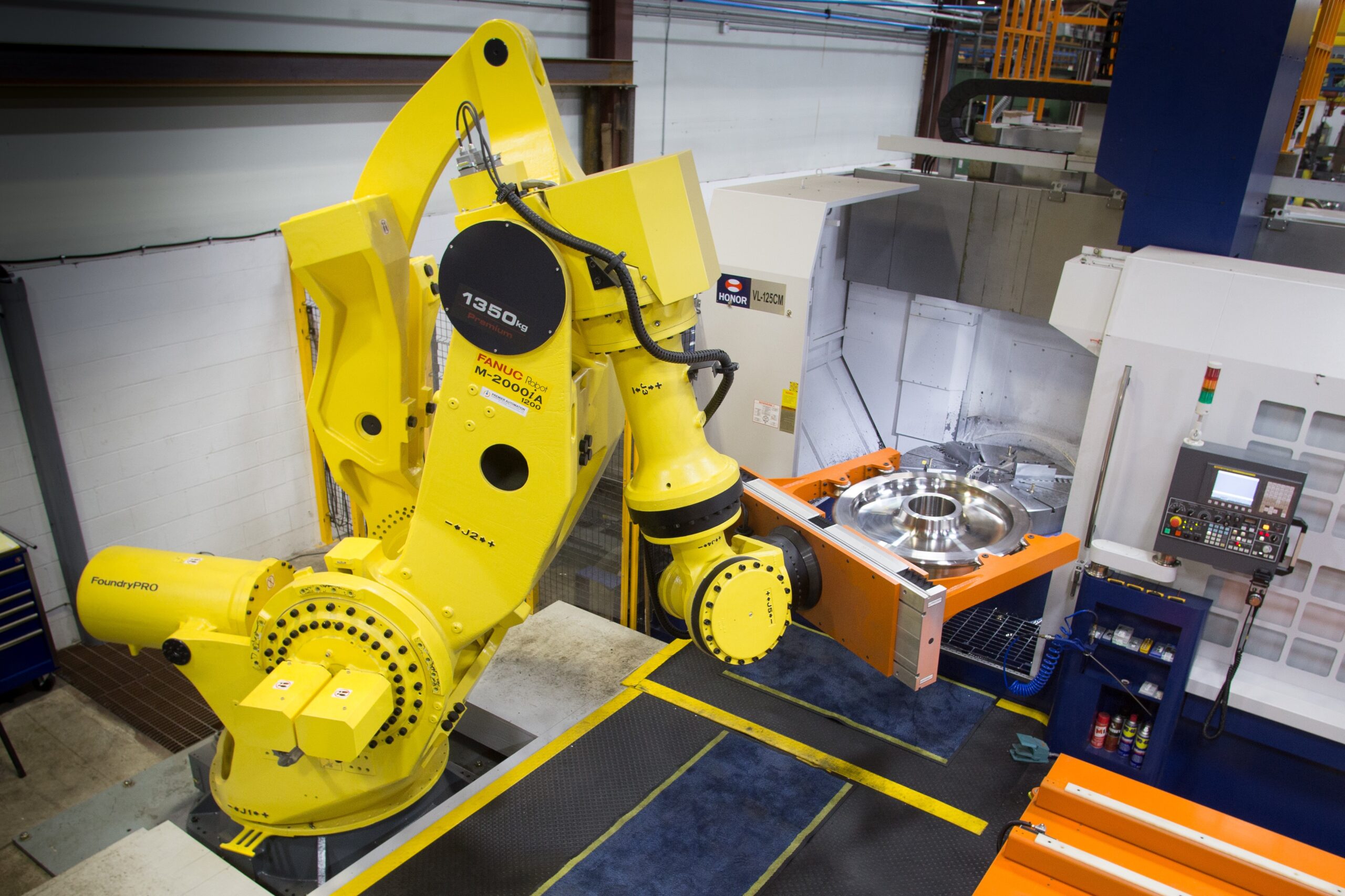

Blairsville, PA, March 27, 2019 – Penn Machine, a manufacturer of wheels, axles, and related equipment for transit, railroad, mining, oil & gas, and industrial applications, has enhanced its Transit Division’s machining capacity with the addition of two 1200mm Honor Seiki vertical turning centers to the company’s Blairsville, PA facility. The turning centers use a Fanuc robot to assist with performing workpiece turning of wheels up to 44” in diameter, as well as with live tool drilling, threading, workpiece probing, and tool probing. This capital investment increases Penn Machine’s ability to manufacture solid wheels that meet the tightest tolerances.

“The addition of the most modern equipment to our production floor highlights our ongoing commitment to excellence,” says John Santarlas, president of Penn Machine. “Our willingness to continually invest in the latest technologies has helped us remain an industry leader. As we prepare to celebrate our first 100 years in business, acquisition of the machining centers and robotics equipment demonstrates our vision for the future.”

Penn Machine Co. manufactures wheels, wheelsets, axles, gears, and gearboxes for OEM and aftermarket applications in the transit, railroad, oil & gas, industrial and mining sectors. The company also services and rebuilds transit gearboxes and wheelsets. Founded in 1920 as a supplier of replacement parts for coal mining equipment, the company is headquartered in Johnstown, PA, and has operations in Johnstown and Blairsville, PA. Penn Machine is part of The Marmon Group, a global organization of manufacturers owned by Berkshire Hathaway Corp.

For more information, contact Brian Dry at 724.675.7293 or bdry@pennmach.com.