PARTS & SERVICE

Parts & Service That Streamline the Customer Experience

Parts

The types of units we re-build with our gearbox repair kits include:

- Single Reduction

- Double Reduction

We also mount or assemble these components to truck frames used in mass transit, commuter and applications:

- Wheelsets

- Traction Motors

- Brake Equipment

- Suspension Parts

Rubber Parts

As a major supplier of quality LORD rubber components to the rail transit market, we help transit authorities, as well as customers in the industrial and mining sectors:

- Manage Motion

- Minimize Noise

- Reduce Vibration & Shock

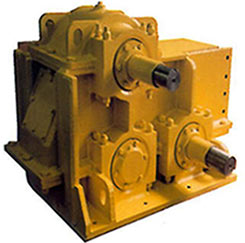

Air Preheater Gearboxes

As an authorized source for new gearboxes used on Ljungström Air Preheaters*, as well as for parts and repairs, we have what you need to keep you up and running.

Air Preheater gearboxes are found in coal and oil-fired power generation stations and converted natural gas plants, chemical plants, paper mills, refineries and other manufacturing facilities. At Penn Machine, we’re the authorized source for these models:

- 3AP

- 4AP

- 5AP

- 7AP

- 8AP

For more information, view our Air Preheater Gearboxes page.

* Ljungström Air Preheater is a registered trademark of ARVOS Inc., Wellsville, NY, formerly Air Preheater Company.

Gear Re-Profiling

We specialize in the restoration of traction (bull) gears. Our Cubic Boron Nitride (CBN) grinding procedure restores the proper involute tooth form for proper gear contact. By removing minimal stock to restore the profile, the restored surface has sufficient hardness and case depth to extend gear life. Typically, we grind in increments of 0.015”, or approximately 3% of tooth thickness.

As a general rule, we recommend re-profiling gear teeth to industry standards when wear exceeds 0.010” of tooth profile. Our re-profiled gears come with 12-month warranties on the profiles only.

Tell us about your specific parts & service requirements so we can help you meet them.